Tornado Protection for Residential and Commercial Structures

Tornado Safe Room Design in accordance with FEMA 320 / 361 and ICC 500

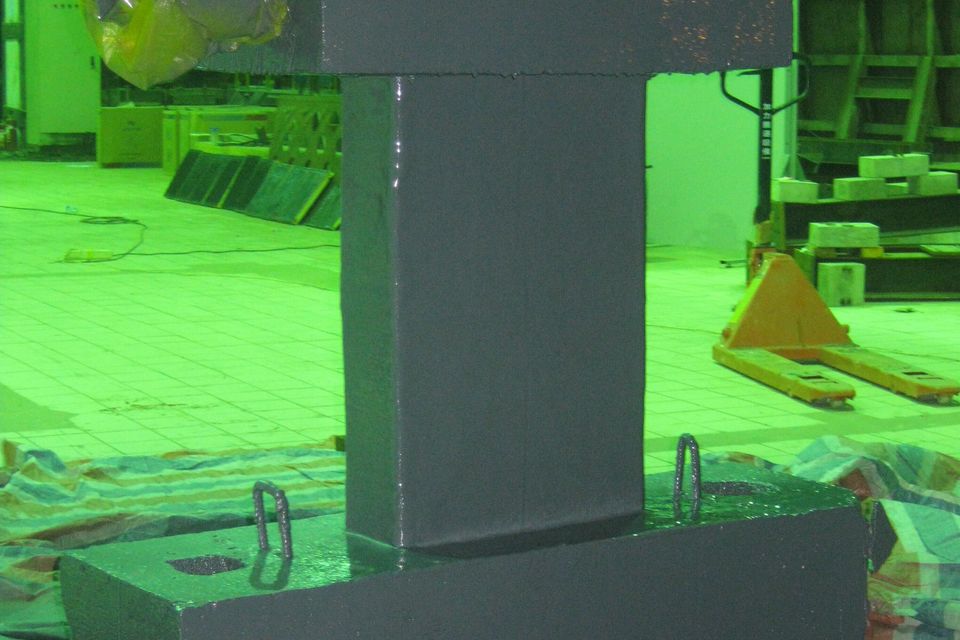

PowerPolymer Solutions' tornado safe room design includes a patent-protected inlay that can tremendously enhance the tornado building envelope in residential structures. See the wall and door test set-ups figures below, (a) and (b).

The thin inlay material, only approximately ¼ inch thick, has a unique chemical composition that has been fundamentally developed from basic science over the last 13 years (starting in 2008) and that allows the walls to withstand high-debris impacts generated by EF-5 rated 250 mph ground wind speed tornados. Our wind-borne debris impact tests were conducted at the National Wind Institute (NWI) at Texas Tech University and in accordance with FEMA 320 and 361, and ICC500 (International Code Council) standards, to meet both construction and testing criteria.

The inlay may be used to protect the wall and door elements of the storm room and is placed inconspicuously between the exterior plywood during construction. See images below.

In door panels, the inlay is placed inconspicuously between the exterior panel of a storm door (constructed using as thin as 18-guage steel) and an embossed veneer. Compared to conventional steel door and expensive carbon-fiber construction options, our unique lightweight functional chemistry-driven design is less than one half the cost; and, unlike carbon-fiber systems, our system passes EF-5 impacts with flying colors. See images below.